Benefits

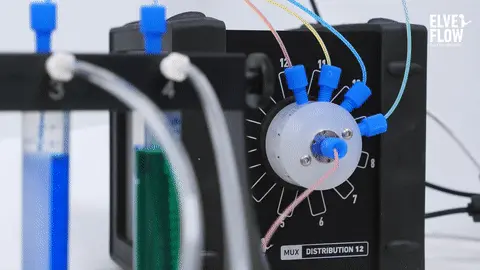

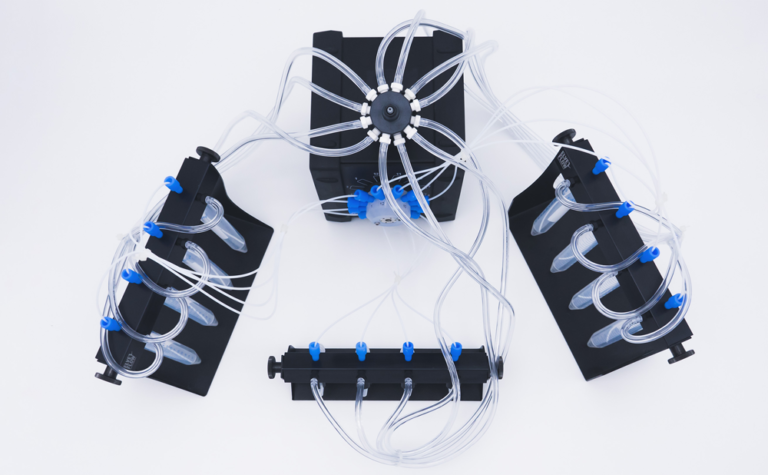

Several solutions from one outlet or one feed directed into different outlets.

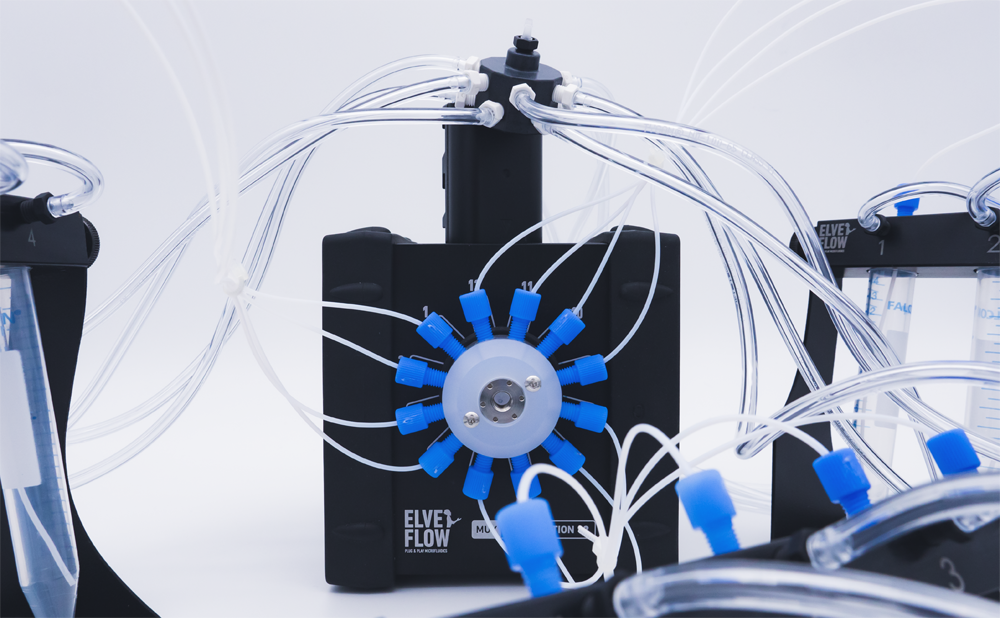

Use the MUX Distribution valve to sequentially inject up 12 different solutions into one microfluidic line for sample collections or parallel experiments.

- Low internal volume

- Fast switching time

- Workflow microfluidic automation

- Smooth switches: no disruption of the flow

- Easy setup and operation (plug and play software + standard fluidic connection)

Bidirectional 13 ports/ 12 positions sequential injection from 12 different samples into 1 output/input

Key advantages

- Valve flexibility: 13 ports

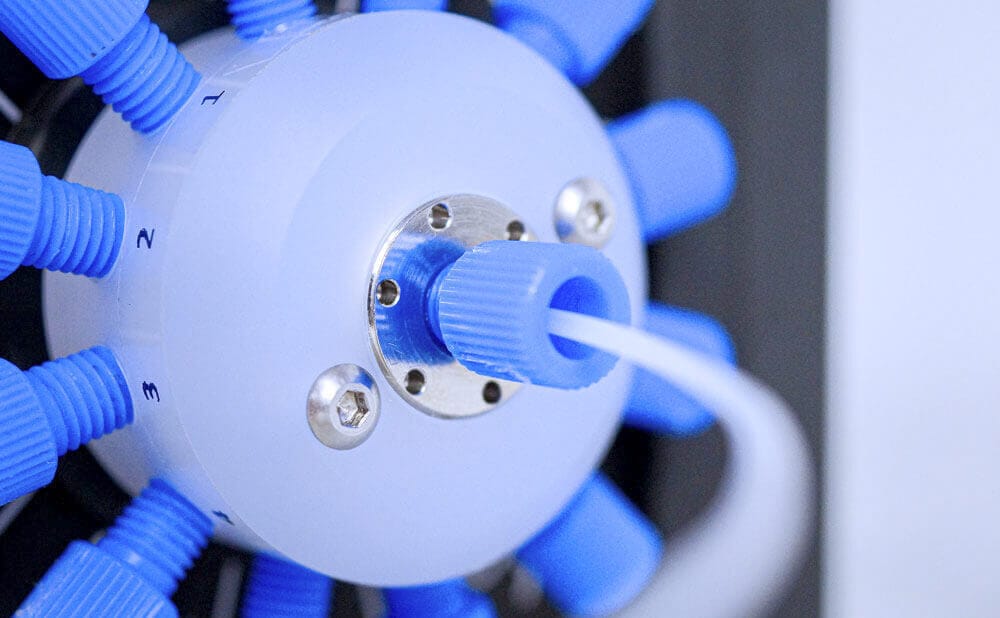

- Easy setup: standard ¼-28 fluidic fittings

- Possibility to chose the sense of rotation

- High chemical compatibility

- Lowest internal volume: 3.5 µL

- No dead volume

- Switching time (average): 156 ms

- Wetted materials: PCTFE, PTFE

Specifications

| NEW 12/1 valve | ||

| Category | Parameter | Value |

| Performances | Port to port switching time (ms) | 156 ms |

| Max recommended pressure | 7 bar | |

| Internal diameter | 0.5 mm | |

| Internal volume(1) | 3.5 µL | |

| Carryover volume(2) | 1.7 µL | |

| Dead volume (3) | None | |

| Wetted materials | PCTFE, PTFE | |

| Number or ports | 13 | |

| Number of positions | 12 | |

| Operating temperature | 5-40°C | |

| Operating Humidity | 20-70% noncondensing |

- Volume inside the system from entrance to exit

- Volume of liquid that will be mixed with the next liquid. It is not stuck, but will be swept next time a liquid passes.

- Volume that is stuck in the system (dead end), which is not clearly swept and relies on diffusion to clear out